All published articles of this journal are available on ScienceDirect.

Criticality Analysis of A Sea Port`s Shore Cranes Using Analytic Hierarchy Process Method

Abstract

Introduction/Background

Critical assets are the organizational resources of crucial importance for maintaining operations and achieving the organization's mission. The criticality of organization assets is continuously researched by numerous authors.

Ports have critical importance for the global supply chain. Together with the port workforce, port infrastructure, and port superstructure, which are interconnected with the port information system, port machinery enables the functioning of a port.

Depending on the characteristics of a port (level of its specialization, etc.), there are various port machinery types used in the cargo handling process, and all of them do not have the same criticality level.

In the available literature, no research directly related to the criticality analysis of shore cranes in use at a terminal in a seaport can be found. It was one of the principal initial motives of the author to write this paper.

Methodology

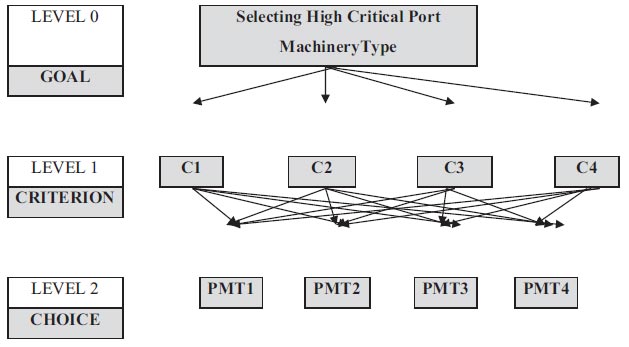

After an overview of literature sources dealing with assets` criticality analysis and a condensed theoretical consideration of the general importance of ports and port machinery, this paper shows the results of research on the port`s shore cranes‘ criticality ranks, using Analytic Hierarchy Process (AHP) method. The research included a group of shore cranes at the Dry Bulk Cargo Terminal in the Port of Bar JSC (Montenegro), which consists of three gantry cranes (with a capacity per item of 12 t), two mobile harbor cranes with a capacity of 144 t and 124 t and a ship loader for cereals with a capacity of 300 t/h. Criticality analysis was conducted based on four selection criteria: C1-if the shore crane type is an element of cargo handling technology with priority cargo group; C2-level of hourly productivity; C3-level of operating costs; C4-level of cost generated by shore crane downtime during the loading/unloading process. The AHP hierarchy framework used was a three-level model: “level 0” – goal; “level 1” the – criterion; “level 2” the – choice.

Results/Discussion

According to the calculated level of criticality based on the defined selection criteria, the highest criticality rank was observed for the mobile harbor crane with a capacity of 144 t, which had the highest rank for three out of four selection criteria.

Conclusion

The results of the research can be used as a base for further research studies in this field as well as a reliable base for a very wide range of managerial activities directed to improvements in the maintenance system of shore cranes as well as in the cargo handling system where the cranes are used. As one of the potential purposes of the results, with a high level of importance, their potential usage for introducing, adequate modeling, and implementing the concept of predictive maintenance of shore cranes (with all related benefits) is pointed out.

1. INTRODUCTION

Effectiveness and efficiency of the decision-making process in an organization (a real system) are functions of the level of adequacy of decision-making bases. Establishing a group of adequate (with the optimal level of reliability) decision-making bases is a challenging phase of the management process, which must be realized methodologically correctly. The nature of the decision-making bases can vary up to a very high level; dominantly, it depends on the characteristics of an organization and the working processes, but it is a definite fact that the group of priority decision-making bases is categorized according to the available assets‘ criticality levels. In a specific way, this is related to a cargo seaport and its shore cranes as a group of assets that determine the role in the cargo handling process/process of providing port services.

The initial stage of the research, whose results are presented in this paper, is a review of available literature aiming to systematize approaches to criticality analysis of organization assets, considerations of the importance of seaports and the relevance of the port machinery as an asset in a seaport with the highest criticality rank.

Ingeneral In general, critical assets are organizational resources of crucial importance for maintaining operations and achieving the organization's mission. Resources belong to the group of critical assets, which, if destroyed or otherwise made unavailable, would affect the system’s reliability or operability [1]. Criticality does not depend only on an asset’s complexity level. It is more related to the effect an asset has on the ability of the system to generate revenue [2]. Criticality is determined by the position of an asset in a system or network and its interconnections with other assets [3]. Defining the criteria for the identification of critical assets is a challenging process, especially regarding internal and external interdependencies, and must be based on appropriate methodology [4]. Asset criticality definition (e.g., “critical infrastructure”) has evolved over the years [5].

Numerous authors have continuously researched the criticality of organization assets. A study describes the core part of asset criticality analysis for Distribution Network Service Providers (DNSPs) [6]. The methodology is based on the risk-based evaluation of assets, considering the potential impacts of their failures on network value. A study proposed a novel framework for physical asset criticality analysis based on the business impact analysis [7]. In another study, the relationship between criticality and risk was studied [8]. A basic risk assessment management model was proposed. The authors of research work presented a design of a criticality assessment tool with particular emphasis on a fertilizer manufacturing company [9]. The objective of the research, whose results are given in a study, is to establish a basis for the criticality analysis of complex in-service engineering assets [10]. The proposed model results in a hierarchy of assets based on risk analysis and cost-benefit principles. Another study took into consideration the critical analysis using the risk-based maintenance technique of petrochemical industries [11]. A research work dealt with criticality assessment as a basic component of Lean Smart Maintenance, dynamic learning, and knowledge-oriented maintenance [12]. It is pointed out there that a targeted optimization of the maintenance strategy is possible through automated evaluation of the assets and identification of the most critical ones. In another research, the development and application of systematic and auditable risk-based criticality ranking was discussed for use in complex plants [13]. In a specific way, the authors highlighted the high importance of auditable criticality assessment. A study described a Criticality Analysis Process Model – a method of prioritizing programs, systems, and components based on their importance to the goals of an organization and the impact that their inadequate operation or loss has on those goals [14]. The authors of a study researched existing decision tools for determining the criticality of asset failure, presented an overview of the alternative methodology, and gave some examples of its practical application [15]. A framework for an agile asset criticality assessment process using a decision-making grid was proposed in a study [16]. The proposed approach is implemented in a petroleum refinery to assess the criticality of the steam generation system. Based on the consideration made in the study, a model of asset risk was created using the traditional Risk-Based Maintenance (RBM) method and fuzzy RBM [17]. It is said that the proposed model can be used to prioritize the assets according to their risk value. One study aimed to explore the factors determining how asset-intensive organizations can achieve reliable outcomes in critical asset introduction despite random failures [18]. Another study presented the methodologies used for asset registration, asset hierarchy, and criticality and risk assessment, gathered from an extensive literature review and interviews with industry experts [19]. A research work gave a practical, systematic approach toward the maintenance procedure optimization of a critical industrial unit in operation by performing a two-phase critical analysis [20]. Through the criticality assessment, fault tree analysis (FTA), vulnerability analysis using a reliability block diagram (RBD), and failure mode effect and criticality analysis (FMECA) were conducted. A criticality analysis of gas infrastructure was developed in order to assess the relative value of these items for the company [21]. It can be taken as an example of how the operation and maintenance strategy is transformed according to criticality assessment. The authors of research work focused on formulating an original agent-based model to explore a crucial pathway through which a disaster affects the economy: the transport-supply chain nexus [22]. The results of the research on the labor-intensive nature of criticality analysis are discussed in a study which are used in asset management to prioritize assets [23]. A machine learning solution is proposed by the development of a criticality analysis model. Two methods for prioritizing maintenance activities are discussed in the study: a traditional qualitative method for task criticality assessment, and a quantitative method that utilizes a fuzzy inference system, mapping the membership functions of two inputs and output accompanied by If-Then rules.

By summarizing the principal elements of the previously analyzed literature sources on the criticality analysis of organization assets, it can be concluded that very different research objects were taken into consideration: distribution network service providers, a fertilizer manufacturing company [9], a petrochemical industry, steam generation system, gas infrastructure, the transport-supply chain nexus, etc [6, 9, 11, 16, 21, 22].

The selection process of the critical assets is very complex, as all valuable assets of an organization have to be identified, classified, and quantified under a common approach within the risk management process [25]. Criticality analysis is an established basis for improving asset availability and reliability, plant safety, and equipment uptime [26].

Ports have critical importance for the global supply chain [27-30]. A study evaluated the ports’ importance from the following four aspects: port resource and ownership, control management, comprehensive services, and innovation-driven aspect [31]. At the same time, ports constitute an important economic activity, having a significant beneficial impact on the economic activities of countries where ports are located and their wider hinterland [32-39]. A study provided a detailed literature review of additional literature regarding the valuation of the economic effects of ports [40]. The importance of ports is researched based on a model of the interrelations between ports and shipping and their socio-economic environment. The potential of ports for job creation and investment is clearly illustrated in research [41]. The European Commission has estimated that by 2030, between 110,000 and 165,000 new jobs can be created in ports.

Port machinery is one of the key technological elements of a port; together with the port workforce, port infrastructure, and port superstructure, interconnected with the port information system, port machinery enables the functioning of a port and significantly contributes to the realization of the supply chain. The general importance of the port machinery is analyzed in different available references. Based on a study and the author`s additional considerations, the following aspects of its general importance can be pointed out: increasing the efficiency of realization of the goods` supply chain where a port appears as a node; reduction of the cost of goods` supply chain realization by reducing the costs of handling operations in a port; increasing the total capacity of a port; increasing the quality of provided port services; reduction of detention of means of transport in a port based on handling operations; improving the level of utilization of means of transport (ships, wagons, trucks); increasing safety at work, reducing the number of occupational diseases and accidents at work, etc [42]. A study stated that port machinery (especially automated handling units) contributes to improving the productivity of a port terminal, reducing the time and costs of each activity, allowing to speed up the freight handling operations by eliminating process interruptions and increasing safety, and reducing the excessive number of workers [43]. At the same time, in another study, port machinery is recognized as the basis for the survival and development of the port terminals [44]. The importance of continuous improvement of cargo handling technologies, where port machinery has a dominant role, can be directly connected with the results of earlier research, where it has been pointed out that improved technologies provide the optimization of port operations and logistics processes and advancements that strengthen the port's position among the maritime communities [45]. In a study, the authors, based on the results of the performed research, concluded that the productivity of the port machinery determines the performance of a terminal (in the concrete case, a container terminal) [46]. Correlations between port machinery and port performance are analyzed in another study. By elaborating on the case study, it can be concluded that having modern port machinery should be taken as a step toward efficient ports [47]. Research focused on the importance of the port machinery for achieving the optimal efficiency level in the cargo handling process at the port terminals [48]. A conclusion that dependence upon labour to manhandle cargo has dramatically decreased is made in this reference, as well. Authors of a study have concluded in their research that handling machinery constitutes the main productive activities that generate income for port industries [49].

The results of a research work that confirms that cargo handling operations are critical to port efficiency have been shown in another study [50]. This conclusion can directly be connected with the importance of port machinery if its decisive role in port operations is taken into account. Focusing on the direct correlation between the general efficiency of port terminals and the characteristics of the cargo handling process, theimportance of the port machinery is suggested in a study [51]. In another study, it is stated that port equipment and its management are becoming crucial for a port's efficiency [52].

Keeping in mind the previously mentioned results of the available literature review, it is a clear fact that the general importance of the port machinery is not questionable from different aspects: for optimizing productivity in a port, increasing safety in a port, achieving optimal efficiency level in a port, port development, improving the market position of a port, etc [42-44, 46-52]. But, it is necessary to take a step forward, taking into account that depending on the characteristics of a port (level of its specialization, etc.), there is a variety of port machinery types used in the cargo handling process, and all of them do not have the same criticality level. So, from different points of view, it is important to define the criticality ranks of the port machinery types used in a port in order to establish bases for the optimization of different working processes in a port, primarily the cargo handling process and port machinery maintenance process.

In the available literature on the criticality analysis of organization assets, the general importance level of the ports, and the role of the port machinery in a port, no research directly related to the criticality analysis of shore cranes in use at any cargo terminal in a port can be found. It was one of the principal initial motives of the author to write this paper.

2. OBJECT OF THE RESEARCH

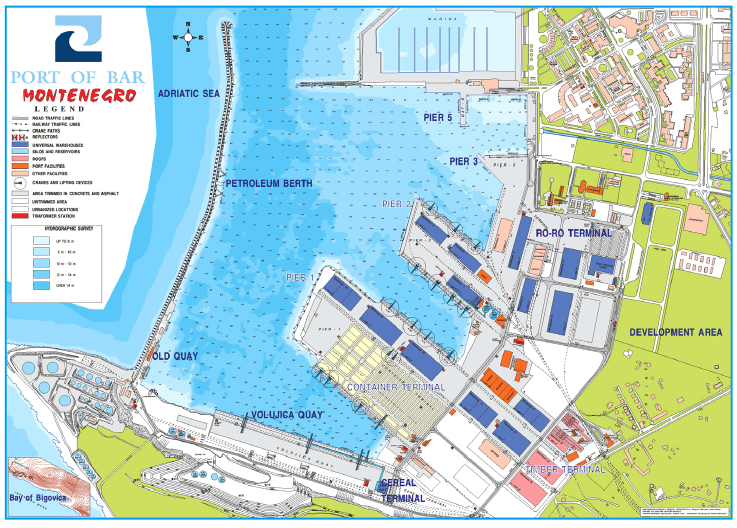

2.1. Basic Characteristics of the Port of Bar

ThePortofBarisa landlord port. It functions based on the Montenegrin Law on ports. In the port area, there are two main port terminal operators: the Port of Bar JSC (a shareholding company where the State of Montenegro owns the major part of shares: 78,55%) and the Port of Adria JSC (a shareholding company where the major part of shares is owned by a company from Turkey: Global Ports Holding - 62%). Following are the specialized terminals in the Port of Bar: liquid cargo terminal, dry bulk cargo terminal, container terminal, general cargo terminal, Ro-Ro terminal, and passenger terminal. Accordingly, the main cargo groups that are handled in the Port of Bar are liquid bulk cargo, dry bulk cargo, general cargo, containers, and Ro-Ro cargo. In the throughput structure, passengers are also included. A map of the Port of Bar is demonstrated in Fig. (1).

The average throughput structure in the Port of Bar JSC from the year 2017 to the year 2021 is shown in Table 1 [53].

The average throughput structure for the period from 2017 to 2021, based on the direction of cargo movements, is given in Table 2 [53].

The priority cargo group is “dry bulk cargo” (with an average share of 79,14% in the overall throughput for the analyzed period); the dominant direction of cargo movement is “export” – on average, 42% of the total handled cargo is exported (loaded to ships). It is of crucial importance to continuously review conclusions about the priority cargo groups and the dominant direction of cargo movement in order to include, in time, all relevant changes in consideration.

A map of the port of bar [53].

| Period | Dry Bulk Cargoes | General Cargoes | Liquid Bulk Cargoes |

|---|---|---|---|

| Average Share [%] | Average Share [%] | Average Share [%] | |

| (1) | (2) | (3) | (4) |

| 2017 - 2021 | 79,14 | 4,01 | 16,85 |

| Period | Import | Export | Transit |

|---|---|---|---|

| Share [%] | Share [%] | Share [%] | |

| (1) | (2) | (3) | (4) |

| 2017 - 2021 | 31,00 | 42,00 | 27,00 |

| Port Machinery Class/type | Number of Available Pieces |

|---|---|

| GANTRY CRANES | - |

| Ceretti e Tanfani, capacity of 12 t, A | 1 |

| Ceretti e Tanfani, capacity of 12 t, B | 1 |

| Ceretti e Tanfani, capacity of 12 t, C | 1 |

| MOBILE HARBOR CRANES | - |

| Liebherr LHM550, capacity of 144 t | 1 |

| Liebherr LHM420, capacity of 124 t | 1 |

| SHIP LOADER (FOR CEREALS) | - |

| PT300-Min Niš, capacity of 300 t/h | 1 |

2.2. Operational Features of the Dry Bulk Cargo Terminal in the Port of Bar JSC

The length of the operational quay at the terminal is 556 m, water depth is up to 14 m, and the maximal allowed vessel draught is 12.80 m. The following shore port machinery is used for loading and unloading cargo to/from vessels: gantry cranes (3 pieces), rail mounted with a capacity of 12 t per item, mobile harbor crane LHM550 on rubber tires, with a capacity of 144 t; mobile harbor crane LHM420 on rubber tires, with a capacity of 124 t and ship loader PT300, with a capacity of 300t/h. The terminal has its own railway network, which is a part of the integral port railway network, directly connected with the Bar–Belgrade (Serbia) railway, with further connections with the Trans-European railway network.

Starting from the basic characteristics of the dry bulk cargo terminal in the Port of Bar JSC and the identified port machinery classes used in the handling operations with cargoes from the priority group (dry bulk cargoes), data on port machinery types used in the process of loading/unloading vessels at the dry bulk cargo terminal is shown in Table 3 [54].

Considering the data given in Table 3, a group of shore cranes, from where the selection of the high critical types will be made, is defined:

o PMT1-Gantry crane - Ceretti e Tanfani, with a capacity of 12 t;

o PMT2-Mobile harbor crane - Liebherr LHM550, with a capacity of 144 t;

o PMT3-Mobile harbor crane - Liebherr LHM420, with a capacity of 124 t;

o PMT4-Ship loader for cereals – PT300-Min Nis, with a capacity of 300 t/h;

3. METHODOLOGY

As stated in the introduction, through the summary of the available literature review, different methods are used for defining the criticality ranks of organization assets: a risk-based methodology for the evaluation of assets; asset criticality analysis based on the business impact analysis, a criticality analysis process model, a method of prioritizing assets based on their importance to the goals of an organization; a framework for theasset criticality assessment process using decision-making grid; the criticality assessment using fault tree analysis (FTA) and failure mode effect and criticality analysis (FMECA); a quantitative method utilizing a fuzzy inference system, mapping the membership functions of two inputs and output accompanied by If-Then rules, etc [6-8, 10, 11, 13, 14, 16, 17, 20, 24].

Pairwise comparison is one of the widely used methods for criticality analysis. A whole list of assets is ranked by comparing only two assets at a time and assigning a numerical rating to the comparison. There are numerous variants of the pairwise comparison method. One such widely accepted method is the Analytic Hierarchy Process (AHP), which is used to analyze the criticality of the shore cranes installed at the dry bulk cargo terminal in the Port of Bar JSC, as identified in the previous chapter of this paper.

The AHP method is widely used for selecting critical assets; it is used to define the priority ranks of assets according to their criticality [55]. As an illustration, the author`s Google inquiry “the selection of critical assets using AHP method” was answered with 38,000 results. In a study, the areas where the AHP is implemented were analyzed (as mentioned in related literature sources): manufacturing systems, software evaluation, supplier selection, selection of recycling technology, construction method selection, warehouse selection, technology evaluation, etc [56]. There are numerous available references where the results of research (based on the implementation of the AHP method) related to seaports are shown: port selection, port competitiveness, selection of cargo handling equipment as a part of the investing process, etc [57-65].

AHP is a method used for solving complex problems at different hierarchical levels, where the goal is at the top level, the intermediate levels are the criteria and subcriteria, and the lowest level is the alternative (choice) [66]. In principle, the AHP is a general theory of measurement used to define ratio scales for both discrete and continuous paired comparisons [4].

As pointed out in a study, the process of paired comparisons has a very broad range of uses for making decisions from four different standpoints: the benefits (B) that the decision brings, the opportunities (O) it creates, the costs (C) that it incurs and the risks (R) that it might generate [67].

The principal steps in the process of criticality analysis using the AHP method are (steps are defined using some elements from a study [66]):

(i) Define the Objective

The objective of the process is to select the highest critical crane type from the group of shore cranes installed at the dry bulk terminal in the Port of Bar JSC used in handling operations of dry bulk cargoes on the relation open storage area/vessel.

(ii) Set the Criteria and Subcriteria

Keeping in mind the key features of the research object, the following selection criteria are set: C1-if the shore crane type is an element of cargo handling technology with priority cargo group; C2-level of hourly productivity; C3-level of operating costs; C4-level of cost generated by shore crane downtime during the loading/unloading process.

(iii) Construct a Hierarchy Framework for the Analysis

The general form of the hierarchy framework for the analysis is demonstrated in Fig. (2).

(iv) Collection of empirical information and data

(v and vi) Pairwise comparison and consistency test

In order to conduct pairwise comparisons and related consistency tests, it is necessary to perform the following steps [66-68]:

Step 1: Create a reciprocal (comparison) matrix based on the number of items for comparison, n (Table 4), and Saaty`s fundamental scale of absolute numbers (Table 5);

Hierarchy framework for the analysis – general form.

Step 2: summing each column of the reciprocal (comparison) matrix;

Step 3: dividing each element of the reciprocal (comparison) matrix with the sum of its columns and getting the normalized relative weights;

Step 4: calculating the normalized principal eigenvector (priority vector), w, by averaging across the rows of the matrix;

Step 5: Calculating principal eigen value λmax obtained from the summation of the products between each element of eigen vector and the sum of columns of the reciprocal (comparison) matrix;

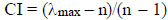

Step 6: Calculating consistency Index, CI, as a measure of deviation or degree of consistency using the following equation:

(1)

(1)

whereλmax - principal eigen value; n - number of items for comparison;

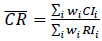

Step 7: calculating Consistency Ratio, CR, based on the values of Consistency Index, CI, and Random Consistency Index, RI (values from Table 6, according to the number of items to be compared; for the analyzed case, n = 4 ⇒ RI = 0,9), as per the following equation (if the value of Consistency Ratio is under 0,10, then the made evaluation is consistent);

(2)

(2)

Step 8: Calculating the overall composite weight of each alternative based on the weights of level 1 and level 2; in fact, the overall weight is just the normalization of the linear combination of multiplication between weight and priority eigenvector;

Step 9: Calculating the overall consistency of the hierarchy by summing all the levels, with the weighted consistency index CI in the nominator, and weighted random consistency RI in the denominator, based on the following relation (if the value of overall Consistency Ratio is under 0,10, the made evaluation is consistent):

(3)

(3)

(vii) Calculate the global weights

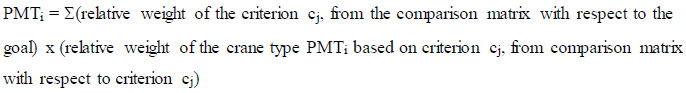

The overall composite weight for the analyzed shore crane types, PMTi, is calculated based on the following relation:

| Number of Things | 1 | 2 | 3 | 4 | 5 | 6 | 7 | n |

|---|---|---|---|---|---|---|---|---|

| Number of comparisons | 0 | 1 | 3 | 6 | 10 | 15 | 21 | n(n-1)/2 |

| Intensity of Importance | Definition | Explanation |

|---|---|---|

| 1 | Equal Importance | Two activities contribute equally to the objective |

| 2 | Weak or slight | - |

| 3 | Moderate importance | Experience and judgment slightly favor one activity over another |

| 4 | Moderate plus | - |

| 5 | Strong importance | Experience and judgment strongly favor one activity over another |

| 6 | Strong plus | - |

| 7 | Very strong or demonstrated importance | An activity is favored very strongly over another; its dominance is demonstrated in practice |

| 8 | Very, very strong | - |

| 9 | Extreme importance | The evidence favoring one activity over another is of the highest possible order of affirmation |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0,58 | 0,9 | 1,12 | 1,24 | 1,32 | 1,41 | 1,45 | 1,49 |

(4)

(4)

(viii and ix) Synthesizing the results and sensitivity analysis

(x) Final Ranking

4. RESULTS

4.1. Basis for Creating Paired Comparison Matrices

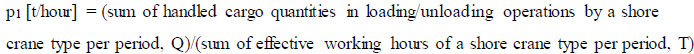

4.1.1. Mean Hourly Productivity Rate Per Shore Crane Type in the Process of Loading (unloading) Ships with Cargo from the Priority Group

In general, hourly productivity is one of the preferred key performance indicators for measuring port performance and has different variants [69, 70]. The relationship between mean hourly productivity rates, p1 (t/hour), and per shore crane type in the process of loading (unloading) vessels with cargo from the priority group (dry bulks) for the period from 2017 to 2021is given in Table 7 [71]. Calculations are based on data from official reports generated in the Port of Bar Information System. The values of mean hourly productivity for gantry cranes are replaced with “1.00”; after this, relative weights are defined. Calculated mean values take into consideration the characteristics of vessels loaded (unloaded) during the analyzed period, the characteristics of cargo handled, different phases of the vessel loading (unloading) process, etc.

Mean hourly productivity is calculated based on the following equation [71]:

(5)

(5)

Table 8 shows the calculated values of the expected productivity rates per working shift, ps[t/shift], for different combinations of shore crane types used in the loading/unloading process of a vessel (with cargo from the priority group). As a basic combination is set, the one which considers the usage of one gantry crane, the related value of expected productivity is replaced with “Ps1”, and the relative proportions between the basic and remaining combinations are established (the comparison between expected productivity per analyzed combination of used shore cranes is based on the data on hourly productivity given in Table 7).

4.1.2. Shore Crane Contribution to Achieving the Contracted Value of Productivity/avoiding Demur-rage Costs Related to a Vessel Loaded/unloaded with Priority Cargo Group

Demurrage is a result of a failure to abide by the rules agreed to in a charter agreement. Specifically, it occurs when a charge is payable to the owner of a chartered vessel for the failure to load or discharge the vessel within an agreed period [72-74]. In order to make a base for the conclusion of which type of group of analyzed shore cranes is contributing the most to avoiding demurrage costs, an analysis is performed; the calculated values of expected productivity per shift for different combinations (Table 8) are ranked (from the highest value to the lowest value) and, after that, the contribution of all shore cranes to achieving overall productivity is defined. The results are presented in Table 9.

Based on the results shown in Tables 7 and 9, a conclusion is made that mobile harbor crane LHM420 and mobile harbor crane LHM550 contribute the most to avoiding demurrage costs for the port in the process of loading/unloading vessels with cargoes from the priority group (dry bulks).

| Port Machinery Class/type | Hourly Productivity Rate [t/hour] – Relative Weights |

|---|---|

| GANTRY CRANE | - |

| Ceretti e Tanfani, SWL 12 t, A | 1,00 |

| Ceretti e Tanfani, SWL 12 t, B | 1,00 |

| Ceretti e Tanfani, SWL 12 t, C | 1,00 |

| MOBILE HARBOR CRANE | - |

| Liebherr LHM550, SWL 144 t | 2,50 |

| Liebherr LHM420, SWL 124 t | 2,00 |

| SHIP LOADER (FOR CEREALS) | - |

| PT300-Min Niš | 1,57 |

| Combination of Shore Crane Types Used, Ci | Hourly Productivity Per Shore Crane Type [t/hour] | Expected Productivity Per Shift [t/shift] (Effective Working Hours: 7,5 hours), Relative Weights |

|---|---|---|

| (1) | (2) | (3) = 7,5 h x (2) |

| Combination – C1 | - | - |

| Gantry crane Ceretti e Tanfani, 12t | 1,00 | Ps1 |

| Combination – C1 | Ps1 | |

| Combination – C2 | - | - |

| Gantry crane Ceretti e Tanfani, 12t | 1,00 | Ps1 |

| Gantry crane Ceretti e Tanfani, 12t | 1,00 | Ps1 |

| Combination – C2 | 2Ps1 | |

| Combination Ci | Expected Productivity Rate Per Shift, Ps [t/shift] | Gantry Crane Ceretti e Tanfani A, 12 t | Gantry Crane Ceretti e Tanfani B, 12 t | Gantry Crane Ceretti e Tanfani C, 12 t | Mobile Harbor Crane LHM420, 124 t | Mobile Harbor Crane LHM550, 144 t |

|---|---|---|---|---|---|---|

| (1) | (2) | (3) | (4) | (5) | (6) | (7) |

| 1 Combination C11 | 7,5 Ps1 | 13,3% | 13,3% | 13,3% | 26,7% | 33,3% |

| 2 Combination C8 | 6,5Ps1 | 15,4% | 15,4% | - | 30,7% | 38,5% |

| 3 Combination C5 | 5,5 Ps1 | 18,1% | - | - | 36,4% | 45,5% |

| 4 Combination C10 | 5,5 Ps1 | 18,1% | 18,1% | 18,1% | - | 45,5% |

| 5 Combination C9 | 5Ps1 | 20% | 20% | 20% | 40% | - |

| ... | - | - | - | - | - | - |

| 14 Combination C1 | Ps1 | 100% | - | - | - | - |

4.1.3. Hourly Operating Cost Per Shore Crane Type

Under this segment, considerations on hourly operating costs per analyzed shore crane type are made. The values related to a gantry crane are replaced with “1,00”, and after that, relative weights are established (Table 10).

| Port Machinery Class/type | Operating Costs, Relative Weights [EUR/hour] |

|---|---|

| GANTRY CRANE | - |

| Ceretti e Tanfani, SWL 12 t, A | 1,00 |

| Ceretti e Tanfani, SWL 12 t, B | 1,00 |

| Ceretti e Tanfani, SWL 12 t, C | 1,00 |

| MOBILE HARBOR CRANE | - |

| Liebherr LHM550, SWL 144 t | 2,86 |

| Liebherr LHM420, SWL 124 t | 2,35 |

| SHIP LOADER (FOR CEREALS) | - |

| PT300-Min Niš | 0,46 |

The values of operating costs (cost of energy/fuel consumption and labor cost of operators), given in Table 10, are calculated based on fuel and electric energy prices, as well as labor costs, which were actual for the date 31st March, 2023. It is clear that the variations in electric energy price, fuel price, and labor costs have a strong influence on the presented results. Just to add, gantry cranes and ship loaders (for cereals) use electric power, and mobile harbor cranes use diesel fuel.

4.2. Pairwise Comparison and Consistency Test

Following the defined phases of the methodology (chapter 3 of this paper), in this segment of the paper, reciprocal matrices are created and related parameters are calculated, all in order to define priority ranks (criticality levels) of analyzed shore cranes (PMTi) based on adopted selection criteria (Cj).

4.2.1. Pairwise Comparison and Consistency Test – Level 1 of the Hierarchy Framework

A reciprocal (comparison) matrix, Level 1 of the hierarchy framework (Fig. 2), with respect to the goal, is shown in Table 11. It is created based on the number of items for comparison, n=4 (Table 4), and Saaty`s fundamental scale of absolute numbers (Table 5). Each column of Table 11 is summed (bottom row of the table), and after that, each element of the table is divided with the sum of its columns in order to get the normalized relative weights. In the next step, the normalized principal eigenvector (Priority Vector), w, is calculated by averaging across the rows of the matrix.

In order to perform a consistency test of the evaluation, it is necessary to calculate the principal eigenvalueλmax – the summation of the products between each element of the eigenvector (Priority Vector) and the sum of columns of the reciprocal (comparison) matrix; Consistency Index, CI, based on the relation (1) and Consistency Ratio, CR, based on the relation (2). If the value of the Consistency Ratio is under 0,10, then the made evaluation is consistent). The calculated values are as follows:

| Criterion | C1 | C2 | C3 | C4 | Priority Vector |

|---|---|---|---|---|---|

| C1 | 1,00 | 3,00 | 5,00 | 2,00 | 0,4764 |

| C2 | 0,33 | 1,00 | 3,00 | 0,50 | 0,1753 |

| C3 | 0,20 | 0,33 | 1,00 | 0,33 | 0,0800 |

| C4 | 0,50 | 2,00 | 3,00 | 1,00 | 0,2683 |

| sum | 2,03 | 6,33 | 12,00 | 3,83 | 1,0000 |

Principal eigen value λmax = 4,0647; Consistency Index, CI = 0,0216; Random Consistency Index, RI = 0,9; Consistency Ratio, CR = 0,0239; Consistency Ratio under 0,10, means that the performed evaluation is consistent.

4.2.2. Pairwise Comparisons and Consistency Tests – Level 2 of the Hierarchy Framework

A reciprocal (comparison) matrix, Level 2 of the hierarchy framework (Fig. 2), with respect to the selection criteria, is shown in Tables 12-15. All the previously mentioned parameters are calculated in line with the described procedure.

| Criterion | PMT1 | PMT2 | PMT3 | PMT4 | Priority Vector |

|---|---|---|---|---|---|

| PMT1 | 1,00 | 0,33 | 0,50 | 2,00 | 0,1572 |

| PMT2 | 3,00 | 1,00 | 2,00 | 5,00 | 0,4827 |

| PMT3 | 2,00 | 0,50 | 1,00 | 3,00 | 0,2720 |

| PMT4 | 0,50 | 0,20 | 0,33 | 1,00 | 0,0881 |

| sum | 6,50 | 2,03 | 3,83 | 11,00 | 1,0000 |

Principal eigen value λmax = 4,0127; Consistency Index, CI = 0,0042; Random Consistency Index, RI = 0,9; Consistency Ratio, CR = 0,0047; Consistency Ratio, CR, is under 0,10, which means that the performed evaluation is consistent.

| Criterion | PMT1 | PMT2 | PMT3 | PMT4 | Priority Vector |

|---|---|---|---|---|---|

| PMT1 | 1,00 | 0,25 | 0,33 | 3,00 | 0,1373 |

| PMT2 | 4,00 | 1,00 | 3,00 | 6,00 | 0,5338 |

| PMT3 | 3,00 | 0,33 | 1,00 | 4,00 | 0,2632 |

| PMT4 | 0,33 | 0,17 | 0,25 | 1,00 | 0,0657 |

| sum | 8,33 | 1,75 | 4,58 | 14,00 | 1,0000 |

Principal eigen value λmax = 4,2031; Consistency Index, CI = 0,0677; Random Consistency Index, RI = 0,9; Consistency Ratio, CR = 0,0752; Consistency Ratio, CR, is under 0,10, which means that the performed evaluation is consistent.

Principal eigenvalue, λmax = 4,0347; Consistency Index, CI = 0,0116; Random Consistency Index, RI = 0,9; Consistency Ratio, CR = 0,0129; Consistency Ratio, CR, is under 0,10, which means that the performed evaluation is consistent.

| Criterion | PMT1 | PMT2 | PMT3 | PMT4 | Priority Vector |

|---|---|---|---|---|---|

| PMT1 | 1,00 | 3,00 | 2,00 | 0,50 | 0,2773 |

| PMT2 | 0,33 | 1,00 | 0,50 | 0,25 | 0,0958 |

| PMT3 | 0,50 | 2,00 | 1,00 | 0,33 | 0,1608 |

| PMT4 | 2,00 | 4,00 | 3,00 | 1,00 | 0,4661 |

| sum | 3,83 | 10,00 | 6,50 | 2,08 | 1,0000 |

| Criterion | PMT1 | PMT2 | PMT3 | PMT4 | Priority Vector |

|---|---|---|---|---|---|

| PMT1 | 1,00 | 0,25 | 0,33 | 3,00 | 0,1373 |

| PMT2 | 4,00 | 1,00 | 3,00 | 6,00 | 0,5338 |

| PMT3 | 3,00 | 0,33 | 1,00 | 4,00 | 0,2632 |

| PMT4 | 0,33 | 0,17 | 0,25 | 1,00 | 0,0657 |

| sum | 8,33 | 1,75 | 4,58 | 14,00 | 1,0000 |

Principal eigen value λmax = 4,2031; Consistency Index, CI = 0,0677; Random Consistency Index, RI = 0,9; Consistency Ratio, CR = 0,0752; Consistency Ratio, CR, is under 0,10, which means that the performed evaluation is consistent.

4.3. Calculating Overall Composite Weights (Synthesizing Results) and Final Ranking

The overall composite weight of each alternative (shore crane type) is based on the calculated weights of Level 1 and Level 2. It is just the normalization of the linear combination of multiplication between weight and priority eigenvector (Priority Vector).

The overall composite weight for the analyzed shore crane types, PMTi, is calculated based on Equation (4):

PMT1 = (0,4764 x 0,1572) + (0,1753 x 0,1373) + (0,0800 x 0,2773) + (0,2683 x 0,1373) = 0,1580

PMT2 = (0,4762 x 0,4827) + (0,1753 x 0,5338) + (0,0800 x 0,0958) + (0,2683 x 0,5338) = 0,4744

PMT3 = (0,4764 x 0,2720) + (0,1753 x 0,2632) + (0,0800 x 0,1608) + (0,2683 x 0,2632) = 0,2588

PMT4 = (0,4764 x 0,0881) + (0,1753 x 0,0657) + (0,0800 x 0,4661) + (0,2683 x 0,0657) = 0,1084

The overall composite weight of the analyzed alternatives is presented in the following matrix (Table 16). In Table 16, the value of column C1 is equal to that of Priority Vector from Table 12; The value of column C2 is equal to that of Priority Vector from Table 13; the value of columnC3 is equal to that of Priority Vector from Table 14; the value of column C4 is equal to that of Priority Vector from Table 15.

| - | C1 | C2 | C3 | C4 | Composite Weight |

|---|---|---|---|---|---|

| PMT1 | 0,1572 | 0,1373 | 0,2773 | 0,1373 | 0,1580 |

| PMT2 | 0,4827 | 0,5338 | 0,0958 | 0,5338 | 0,4744 |

| PMT3 | 0,2720 | 0,2632 | 0,1608 | 0,2632 | 0,2588 |

| PMT4 | 0,0881 | 0,0657 | 0,4661 | 0,0657 | 0,1084 |

The overall consistency of the hierarchy, CR, calculated based on equation (3), is 0,0303 (under 0,10), which means that the complete evaluation (at level 1 and level 2) is consistent.

5. DISCUSSION

Based on the research results shown in the previous chapter, the following overall criticality ranking (taking into account all selection criteria) of shore crane types at the dry bulk cargo terminal in the Port of Bar JSC is defined:

-Rank 1 (the shore crane type with the highest criticality rank): PMT2 – Mobile harbor crane - Liebherr LHM550 (capacity: 144 t), with a composite weight of 0,4744 (47,44%);

-Rank 2: PMT3 - Mobile harbor crane - Liebherr LHM420 (capacity: 124 t), with a composite weight of 0,2588 (25,88%);

-Rank 3: PMT1 – Gantry crane - Ceretti e Tanfani (capacity: 12 t), with a composite weight of 0,1580 (15,80%);

-Rank 4 (the shore crane type with the lowest criticality rank): PMT4 – Ship loader for cereals – PT300-Min Nis, with a composite weight of 0,1084 (10,84%);

The criticality analysis of shore crane types from the group of shore cranes at the Dry Bulk CargoTerminal in the Port of Bar JSC as per criterion C1(If the shore crane type is an element of cargo handling technology in the priority cargo group) results in the following ranking:

-Rank 1: PMT2-Mobile harbor crane - Liebherr LHM550 (capacity: 144 t), with a calculated weight of 0,4827 (48,27%);

-Rank 2: PMT3-Mobile harbor crane - Liebherr LHM420 (capacity: 124 t), with a calculated weight of 0,2720 (27,20%);

-Rank 3: PMT1-Gantry crane - Ceretti e Tanfani (capacity: 12 t), with a calculated weight of 0,1572 (15,72%);

-Rank 4: PMT4- Ship loader for cereals – PT300-Min Nis (capacity 300 t/h), with a calculated weight of 0,0881 (8,81%);

Criticality analysis of shore crane types from the group of shore cranes at the Dry Bulk Cargo Terminal in the Port of Bar as per criterion C2(level of hourly productivity) results in the following ranking:

-Rank 1: PMT2-Mobile harbor crane - Liebherr LHM550 (capacity: 144 t), with a calculated weight of 0,5338 (53,38%);

-Rank 2: PMT3-Mobile harbor crane - Liebherr LHM420 (capacity: 124 t), with a calculated weight of 0,2632 (26,32%);

-Rank 3: PMT1-Gantry crane - Ceretti e Tanfani (capacity: 12 t), with a calculated weight of 0,1373 (13,73%);

-Rank 4: PMT4- Ship loader for cereals – PT300-Min Nis (capacity 300 t/h), with a calculated weight of 0,0657 (6,57%);

The ranking of shore crane types from the group of shore cranes at the Dry Bulk Caro Terminal in the Port of Bar as per criterion C3 (level of operating costs) is as follows:

-Rank 1: PMT4- Ship loader for cereals – PT300-Min Nis (capacity 300 t/h), with a calculated weight of 0,4661 (46,61%);

-Rank 2: PMT1-Gantry crane - Ceretti e Tanfani (capacity: 12 t), with a calculated weight of 0,2773 (27,73%);

-Rank 3: PMT3-Mobile harbor crane - Liebherr LHM420 (capacity: 124 t), with a calculated weight of 0,1608 (16,08%);

-Rank 4: PMT2-Mobile harbor crane - Liebherr LHM550 (capacity: 144 t), with a calculated weight of 0,5338 (9,58%);

Criticality analysis of shore crane types from the group of shore cranes at the Dry Bulk Caro Terminal in the Port of Bar JSC per criterion C4(level of costs generated by shore crane downtime during the loading/unloading process) results in the following ranking:

-Rank 1: PMT2-Mobile harbor crane - Liebherr LHM550 (capacity: 144 t), with a calculated weight of 0,5338 (53,38%);

-Rank 2: PMT3-Mobile harbor crane - Liebherr LHM420 (capacity: 124 t), with a calculated weight of 0,2632 (26,32%);

-Rank 3: PMT1-Gantry crane - Ceretti e Tanfani (capacity: 12 t), with a calculated weight of 0,1373 (13,73%);

-Rank 4: PMT4- Ship loader for cereals – PT300-Min Nis, with a calculated weight of 0,0657 (6,57%);

Mobile harbor crane Liebherr LHM550 has the highest ranking in three out of four selection criteria:

- It is used in handling operations with priority cargo group (dry bulk) - importance rank: 0,4827, for 77,46% higher compared with the importance of the secondly ranked shore crane ;

- It has the highest hourly productivity – -importance rank: 0,5338, for 102,81% higher compared with the importance of the secondly ranked shore crane type;

- The consequences of its downtime during the ship loading/unloading process are significant – importance rank: 0,5338, as well, for 102,81% higher than the importance of the second-ranked shore crane.

The results can be used as a reliable managerial base for a very wide range of improvements at the terminal analyzed, as well as in the port in general:

- optimizing the overall port efficiency,

- selecting the most appropriate maintenance strategy for shore cranes in accordance with their criticality ranks,

- minimizing working process interruptions,

- defining priorities for investing,

- optimization of spare parts control,

- improving safety at work, etc.

It is worth pointing out the possible usage of the results of shore crane criticality analysis as a basis for introducing the concept of predictive maintenance; when implemented successfully, it reduces operational costs, minimizes downtime issues, improves overall asset performance, etc [75].

CONCLUSION

The results of the research presented in this paper fully confirmed the high levels of AHP method adequacy for defining the criticality levels of shore cranes (and, in general, port machinery) in a seaport. The discussed approach to criticality analysis is related to shore cranes at the Dry Bulk Cargo Terminal in the Port of Bar, JSC, Montenegro, but it is obvious that it could be implemented for selecting high-critical port machinery types at different port terminals (used in different cargo handling operations), which is one of the further planned engagement of author in this domain.The author plans to check (to reconsider) the results presented in this paper using some other research methods, too.

The results of the research can be used by port professionals for improving decision-making in the cargo handling process as well as in the maintenance process of the port machinery. The results can also be used by researchers who are dealing with criticality analysis of organization assets, those who are studying the role and importance of ports in the supply chain, and those who are investigating port machinery from different aspects.

The proposed approach to the shore cranes criticality analysis could be replicated in other similar seaports, too (where cargo loading/unloading operations to/from vessels are done by gantry cranes and/or mobile harbor cranes).

CONFIRMATION

The author confirms that the manuscript (or any part of it) has not been published previously and is not under consideration for publication elsewhere.

LIST OF ABBREVIATIONS

| AHP | = Analytic Hierarchy Process |

| DNSPs | = Distribution Network Service Providers |

| RBM | = Risk-Based Maintenance |

| FMECA | = Failure Mode Effect and Criticality Analysis |

| RBD | = Reliability Block Diagram |

| FTA | = Fault Tree Analysis |